PRODUCT CENTER

Outdoor layer twisted wire (GYTA/GYTS)

2022-06-02

Reference standard: YD/T 901-2009; GB/T 9771-2008

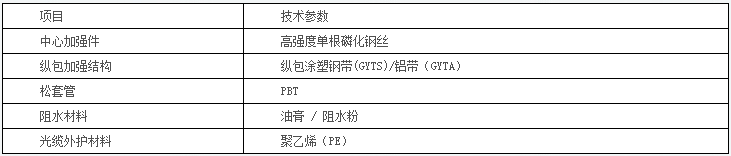

Product Overview: The center loose sleeve and filling rope of the inner colored fiber optic cable are wrapped around the metal center reinforcement key through SZ twisting and cable formation. After that, the cable is longitudinally wrapped with double-sided plastic coated aluminum tape and extruded with PE sheath. The gaps inside the loose sleeve and cable core are filled with waterproof compounds.

Product features:

The structure of GYTS optical cable is to insert single-mode/multimode optical fibers into a loose tube made of high modulus plastic, and fill the tube with waterproof compound

2. The center of the cable core is a metal reinforced core, and for certain numbers of optical cables, a layer of polyethylene (PE) needs to be extruded outside the metal reinforced core

3. Loosen the sleeve around the center to strengthen the core and twist it into a compact circular cable core. The gaps inside the cable core are filled with waterproof filling material

4. Compared to GYTS, GYTA uses longitudinal aluminum strip instead of coated steel strip structure, which slightly reduces physical compressive and tensile strength, but improves waterproofing ability and reduces self weight

5. Plastic coated steel strip (GYTS)/aluminum strip (GYTA) is longitudinally wrapped and extruded into a polyethylene sheath to form a cable. The maximum number of cores for a single GYTA optical cable can reach 144, and the maximum number of cores for GYTS can reach 216

Application scope:

1. Vertical mainline subsystem;

2. Building complex subsystem;

3. Telecommunications operations, metropolitan area networks, and wide area networks

24-hour service hotline

Email:

mingxin8188@126.com

Address:East side of Guoshui Road, Shatou Town, Guangling District, Yangzhou City, Jiangsu Province

【 Wechat 】

Copyright© 2022 Mingxin Intelligent Optics (Jiangsu) Co., Ltd